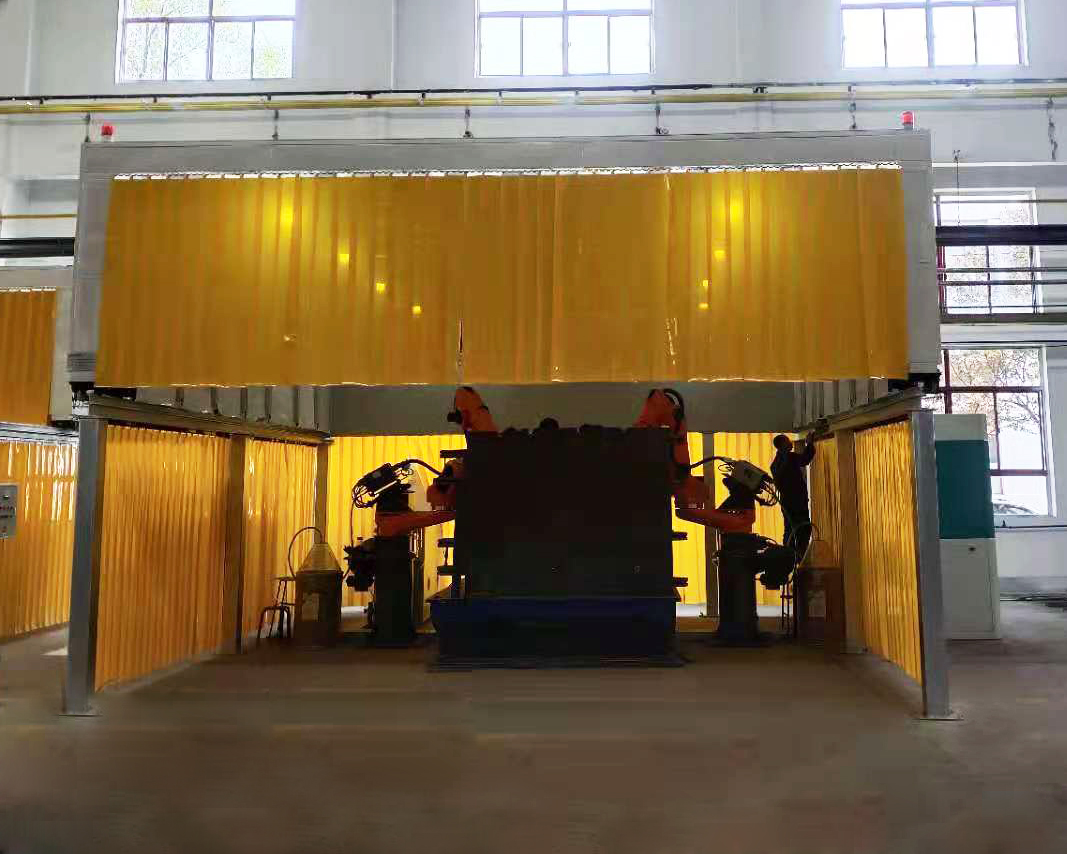

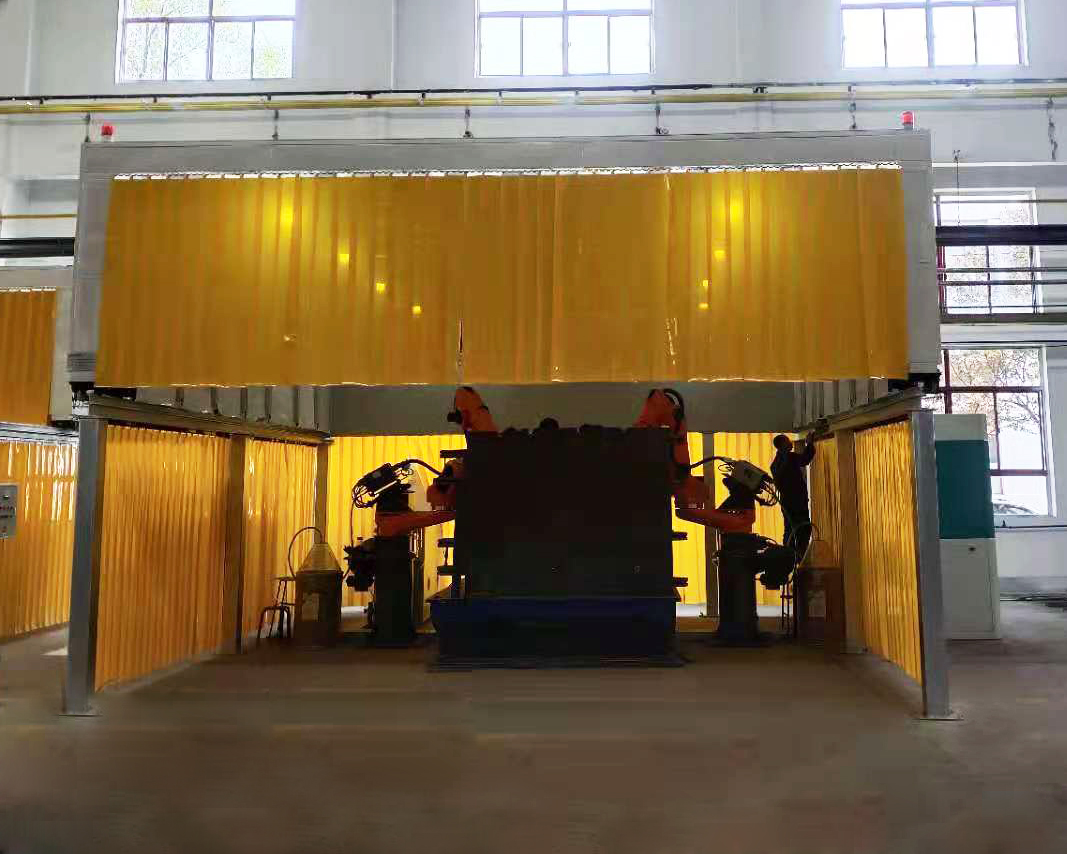

焊煙除塵設備使用使用要注意什么?

來源:http://m.hbrqhj.com/ 發(fā)布時間:2023-07-01

焊煙除塵設備是用于處理焊接產生的有害氣體和顆粒物的裝置。它們主要通過過濾、吸附和除塵等技術來凈化空氣中的有害物質,保護工作環(huán)境和員工健康。以下是焊煙除塵設備的使用步驟:

Welding smoke dust removal equipment is a device used to treat harmful gases and particles generated during welding. They mainly purify harmful substances in the air through technologies such as filtration, adsorption, and dust removal, protecting the working environment and employee health. The following are the usage steps of welding smoke dust removal equipment:

1. 確定設備位置:將焊煙除塵設備放置在產生焊接煙塵的區(qū)域附近,以確保能夠有效收集到煙塵。

1. Determine the location of the equipment: Place the welding smoke and dust removal equipment near the area where welding smoke and dust are generated to ensure effective collection of smoke and dust.

2. 連接管道:使用合適的管道連接焊煙排放口和除塵設備。管道長度應盡量縮短,以減少壓力損失和阻力。

2. Connecting pipelines: Use suitable pipelines to connect the welding smoke discharge outlet and dust removal equipment. The length of the pipeline should be minimized to reduce pressure loss and resistance.

3. 設置風機和風量:根據焊接過程中產生的煙塵量和排放口位置的遠近,調整風機的風量和運行速度。風量需要足夠大以將焊接煙塵吸入設備,并保持壓差在適當范圍內。

3. Set the fan and air volume: Adjust the fan's air volume and operating speed based on the amount of smoke and dust generated during the welding process and the distance of the discharge outlet. The air volume needs to be large enough to suck welding fumes into the equipment and maintain a pressure difference within an appropriate range.

4. 啟動除塵設備:打開焊煙除塵設備主電源,并按照設備操作說明啟動風機和過濾系統(tǒng)。

4. Start the dust removal equipment: Turn on the main power supply of the welding smoke dust removal equipment and follow the equipment operation instructions to start the fan and filtration system.

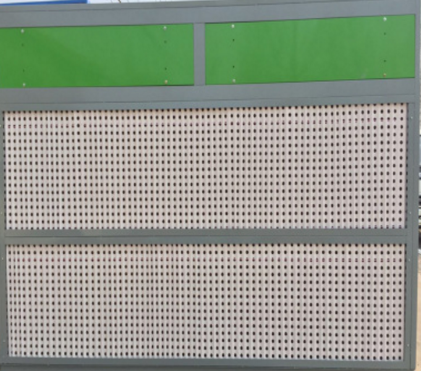

5. 定期檢查維護:定期檢查除塵設備的運行狀況,清理或更換過濾器和吸附劑等消耗品。清理過濾器時,應按照操作說明進行操作,避免對設備造成損壞或污染。

5. Regular inspection and maintenance: Regularly check the operation status of dust removal equipment, clean or replace consumables such as filters and adsorbents. When cleaning the filter, follow the operating instructions to avoid damage or contamination to the equipment.

6. 檢測效果:使用空氣質量監(jiān)測設備或專業(yè)檢測儀器,對除塵設備處理后的空氣進行監(jiān)測,確保排放物符合相關標準和規(guī)定。

6. Testing effect: Use air quality monitoring equipment or professional testing instruments to monitor the air treated by dust removal equipment, ensuring that the emissions comply with relevant standards and regulations.

請注意,在使用焊煙除塵設備之前,應了解當地的環(huán)境保護法規(guī)和安全操作規(guī)程,并確保設備符合相關的認證和標準要求。同時,為了確保設備的有效性和安全性,應定期進行維護和保養(yǎng),并遵循廠家提供的操作指南。

Please note that before using welding fume dust removal equipment, it is important to understand local environmental protection regulations and safety operating procedures, and ensure that the equipment meets relevant certification and standard requirements. At the same time, in order to ensure the effectiveness and safety of the equipment, regular maintenance and upkeep should be carried out, and the operating guidelines provided by the manufacturer should be followed.

上一篇:集中式焊煙除塵器設備組成及特點

下一篇:多工位焊接煙塵凈化系統(tǒng)特點

魯公網安備 37142502000144號

魯公網安備 37142502000144號