噴砂房的局部抽風(fēng)的特點介紹

來源:http://m.hbrqhj.com/ 發(fā)布時間:2023-09-06

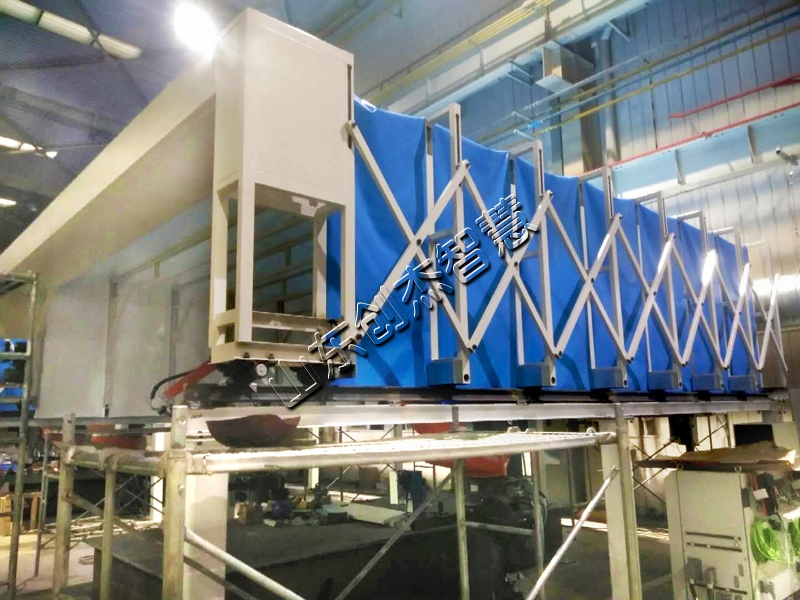

噴砂房適應(yīng)于一些大型工件表面清理、除銹,增加工件與涂層之間的附著力等效果,它在使用時局部抽風(fēng)是什么原理?以下是小編的整理:

The sandblasting room is suitable for surface cleaning and rust removal of some large workpieces, increasing the adhesion between the workpiece and the coating, and other effects. What is the principle of local ventilation when it is used? The following is the editor's organization:

噴砂房設(shè)置了局部通風(fēng)。噴砂房工人戶外作業(yè)噴砂是在密閉的房間內(nèi)進(jìn)行的,抽風(fēng)量的確定是基于噴砂時可以吸走灰塵,看清楚零件表面的原理。風(fēng)量一般可根據(jù)噴砂房,室內(nèi)橫截面積風(fēng)速0.3- 0.7 m/s計算,橫截面積根據(jù)氣流方向確定。截面風(fēng)速的選擇應(yīng)考慮噴砂房,緊密度、噴嘴尺寸和噴砂室尺寸等因素。

The sandblasting room is equipped with local ventilation. Outdoor sandblasting is carried out by sandblasting room workers in a closed room, and the determination of ventilation volume is based on the principle of being able to absorb dust and see the surface of parts clearly during sandblasting. The air volume can generally be calculated based on the sandblasting room, and the indoor cross-sectional area wind speed is 0.3-0.7 m/s. The cross-sectional area is determined based on the direction of the airflow. The selection of cross-sectional wind speed should consider factors such as sandblasting room, tightness, nozzle size, and sandblasting room size.

從噴砂房提取的粉塵需要經(jīng)過除塵凈化后才能排放到大氣中。避免除塵不當(dāng)和含塵氣體進(jìn)入本車間其他車間造成環(huán)境污染。拋光拋光機局部通風(fēng):金屬零件在拋光拋光過程中會產(chǎn)生大量的金屬粉塵和纖維粉塵,因此需要設(shè)置局部通風(fēng)來消除。在排入大氣之前,需要除塵凈化。

The dust extracted from the sandblasting room needs to undergo dust removal and purification before it can be discharged into the atmosphere. Avoid improper dust removal and the entry of dusty gases into other workshops in this workshop, causing environmental pollution. Polishing and polishing machine local ventilation: During the polishing and polishing process of metal parts, a large amount of metal dust and fiber dust will be generated, so local ventilation needs to be set up to eliminate it. Before being discharged into the atmosphere, dust removal and purification are required.

噴砂房零件的噴漆一般在噴漆室進(jìn)行,需要一個帶水淋過濾器或干式過濾器的局部排氣裝置,以防止漆霧從工作孔口逸出到室內(nèi)。小零件除銹噴漆可在工作臺或局部通風(fēng)的通風(fēng)柜內(nèi)進(jìn)行,通風(fēng)量按進(jìn)風(fēng)工作孔口截面風(fēng)速0.1m/秒計算。

The painting of parts in the sandblasting room is generally carried out in the painting room, and a local exhaust device with a water spray filter or dry filter is required to prevent paint mist from escaping from the working orifice into the room. The rust removal and painting of small parts can be carried out on the workbench or in a locally ventilated ventilation cabinet, and the ventilation rate is calculated based on the cross-sectional wind speed of 0.1m/s at the inlet of the working hole.

安裝在噴砂房的噴嘴機械手可以對零件表面進(jìn)行自動噴砂,自動噴砂難以到達(dá)的區(qū)域可以通過手動噴砂完成。

The nozzle robotic arm installed in the sandblasting room can automatically sandblasting the surface of parts, and areas difficult to reach by automatic sandblasting can be completed through manual sandblasting.

本文由自動噴砂房提供技術(shù)支持,更多的詳細(xì)精彩內(nèi)容請點擊我們的網(wǎng)站http://m.hbrqhj.com,我們將會全心全意為您提供滿意的服務(wù)。

This article is supported by the automatic sandblasting room. For more detailed and exciting content, please click on our website http://m.hbrqhj.com We will wholeheartedly provide you with satisfactory service.

上一篇:前處理電泳工藝的特點有哪些?

下一篇:噴砂房的局部抽風(fēng)的特點介紹

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號